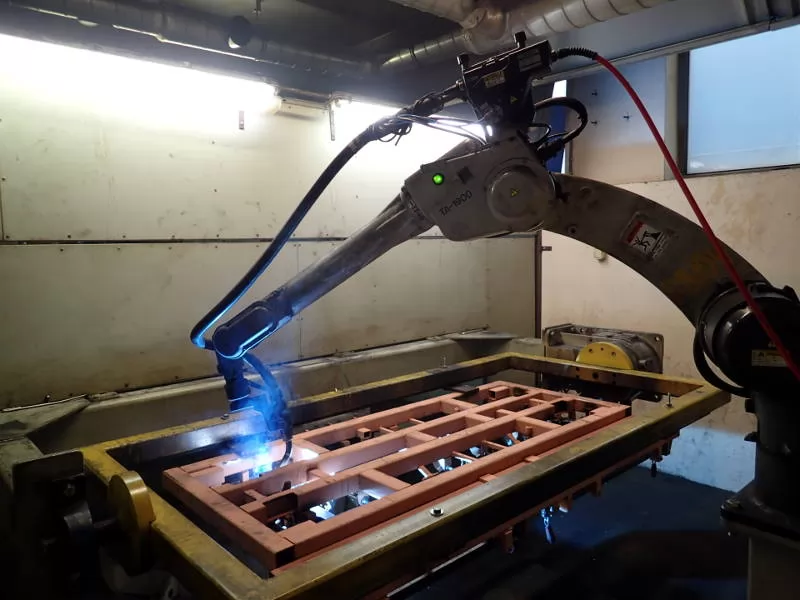

Robotic Welding

Welding on the robotic welding workstation is performed by the Panasonic welding robot TA-1900WG3 and TA-1900WG4 with TOWERS system, that welds metal parts with following dimensions:

Welding on the robotic welding workstation is performed by the Panasonic welding robot TA-1900WG3 and TA-1900WG4 with TOWERS system, that welds metal parts with following dimensions:

- Length up to 2,5 m

- Width up to 1,2 m

- Height up to 1,0 m

- and the weight up to 500 kg.

The use of welding robot Ta-1900 with modern controller G3 and G4 and TOWERS system in comparison with standard manual welding, affects of the quality of product by obtaining:

The use of welding robot Ta-1900 with modern controller G3 and G4 and TOWERS system in comparison with standard manual welding, affects of the quality of product by obtaining:

- high class of welds (stability of the arc parameters, optimization of the location and movement of the torch, wire feeding without collision, intermediate cleaning of the welding torch nozzle),

- repeatable weld ±0,1 mm (location and dimension of weld),

- higher than ever quality,

- product without the spatter,

Thanks to the optimization of complex production and welding processes (elimination of partial welding operations of product components on several workstations, a clean product without welding spatters and with limited to minimum stresses and deformations, not requiring additional technological treatments) we ensure competitive prices.

In January 2019, we launched our fourth robotised stand with a Panasonic welding robot with an 8-metre long running track (dimensions of the welded part: length. 3. 0 m, width. 1. 5 m, height. 1,0 m).

The new mechanics enable super fast idle movements of the robot up to 180m/min. and the virtually splinter-free SP-MAG welding method:

- Hyper Dip Plus - a variant of the pulsed arc which enables high welding speeds, deep penetration and give welds without submerging

- The Arc LiftStart function or splinter-free incident

- Arc LiftEnd function to avoid a crater in the joint.

The robot has the ability to monitor the welding process and welding incompatibilities. The robot s downtime is eliminated and thus its productivity is increased -when the robot welds on one welding stand, the welded parts are dismantled and new ones are installed on the other.

Panasonic is practically the only manufacturer of the so called "Panasonic"; in the world. integrated robotic MIG/MAG/TIG welding systems.

The company is constantly investing in modern machinery to ensure that our welding services are at the highest level which will distinguish us from our competitors.